China is the largest producer of electronics and sets high requirements for the protection of goods from ESD through the use of electrostatic control flooring at production facilities. TUBALL, as one of the most effective additives, has rapidly attracted wide attention from Chinese manufacturers since OCSiAl entered the regional market.

“The flooring industry is one of the premier fields to realise the advantages of single wall carbon nanotubes. OCSiAl uses the power of nanotechnology to replace general conductive additives with nanotubes, which not only solve the ESD problem, they also meet consumers' expectations for the appearance of products,” commented Loyes Zhi, OCSiAl Managing Director of Greater China.

Compared with conventional additives, the main advantage of TUBALL nanotubes is the ultra-low loadings required, which allow colouration, achieve uniform conductivity of the flooring, and leave a perfect surface finish.

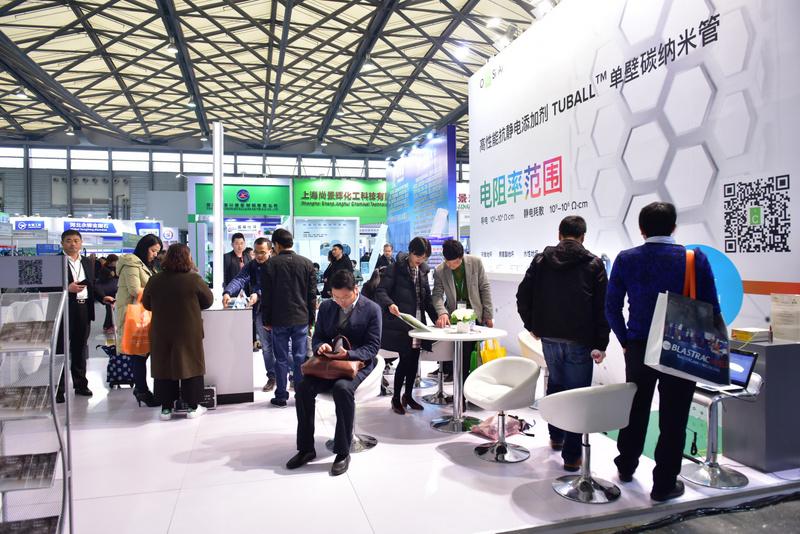

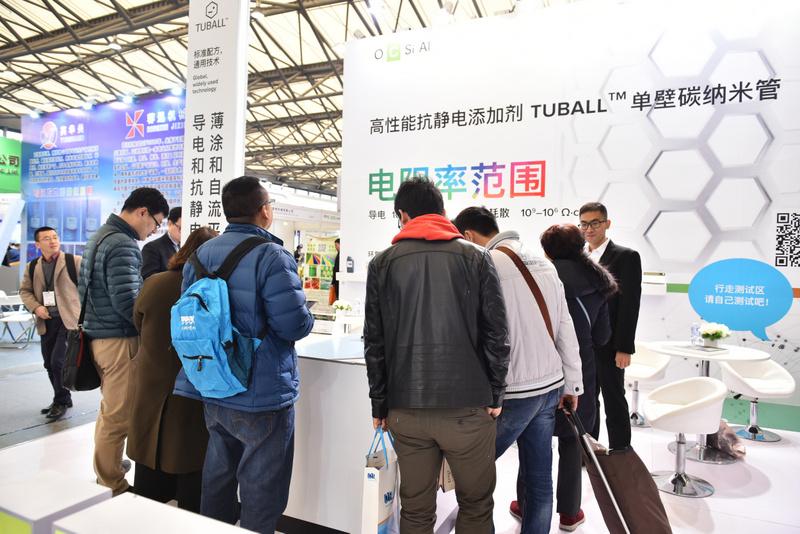

In order to increase the effectiveness of TUBALL nanotubes, OCSiAl has designed various industrial solutions, and these were demonstrated at the China Floor Industry Expo 2017 in Shanghai. The wide range of these solutions includes the nanotube-based products TUBALL COMP_E, TUBALL COAT and TUBALL MATRIX. An ultra-low dosage of just 0.01% of TUBALL nanotubes can achieve a volume resistivity of 10^8 Ω·cm without any significant effect on the viscosity or colour. The nanotubes also prolong the cycle life of the flooring and allow it to be easily recoated, reducing the total cost.

“We were pleased to note that most of the exhibitors at the Expo are already OCSiAl’s partners. A number of the conductive flooring samples demonstrated at these exhibitors’ booths already contain TUBALL nanotubes. Moreover, China Expo brought us more than 100 new business contacts. Around 500 visitors at the OCSiAl booth were really impressed by the ability of TUBALL to provide permanent and uniform conductivity, while allowing colouration, enhancing mechanical properties, and greatly simplifying ESD flooring production,” summarised Loyes Zhi.