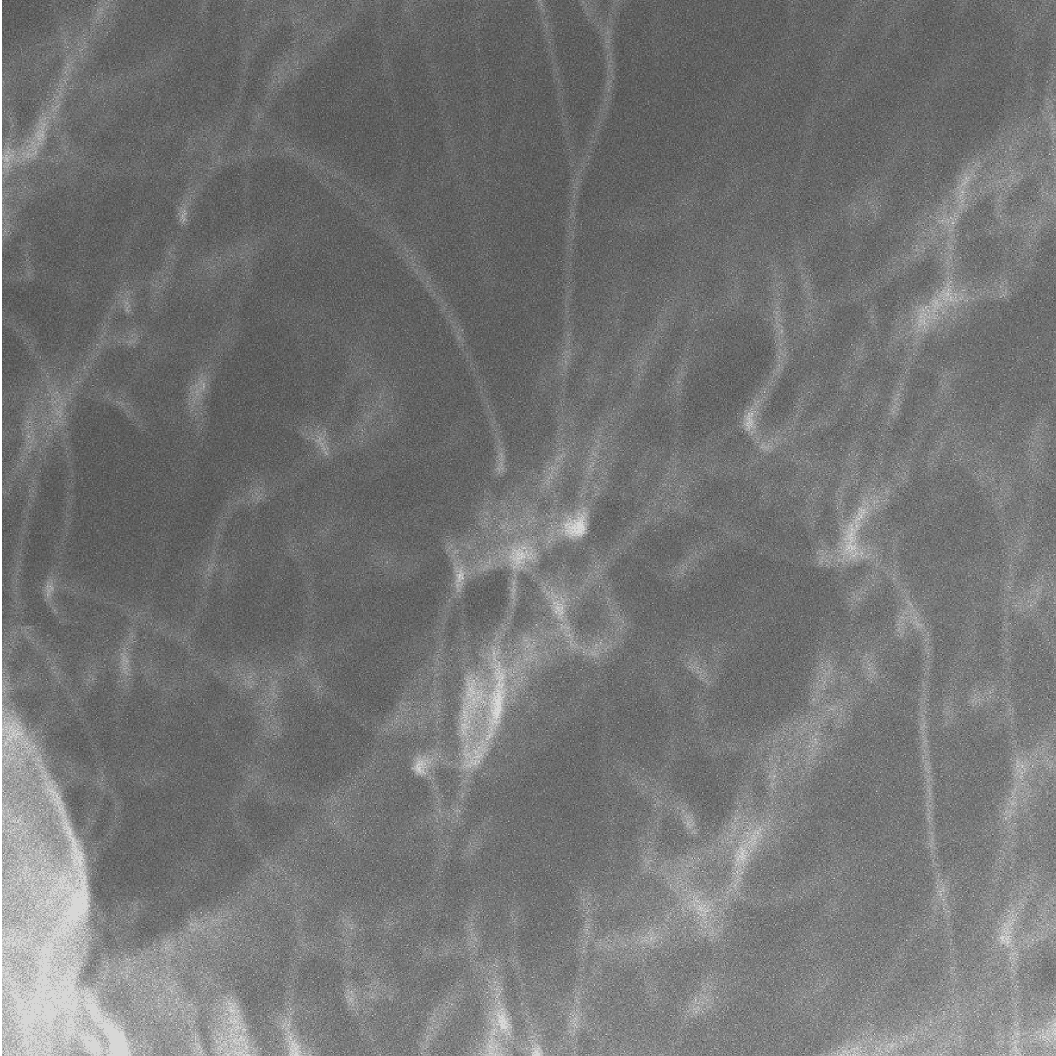

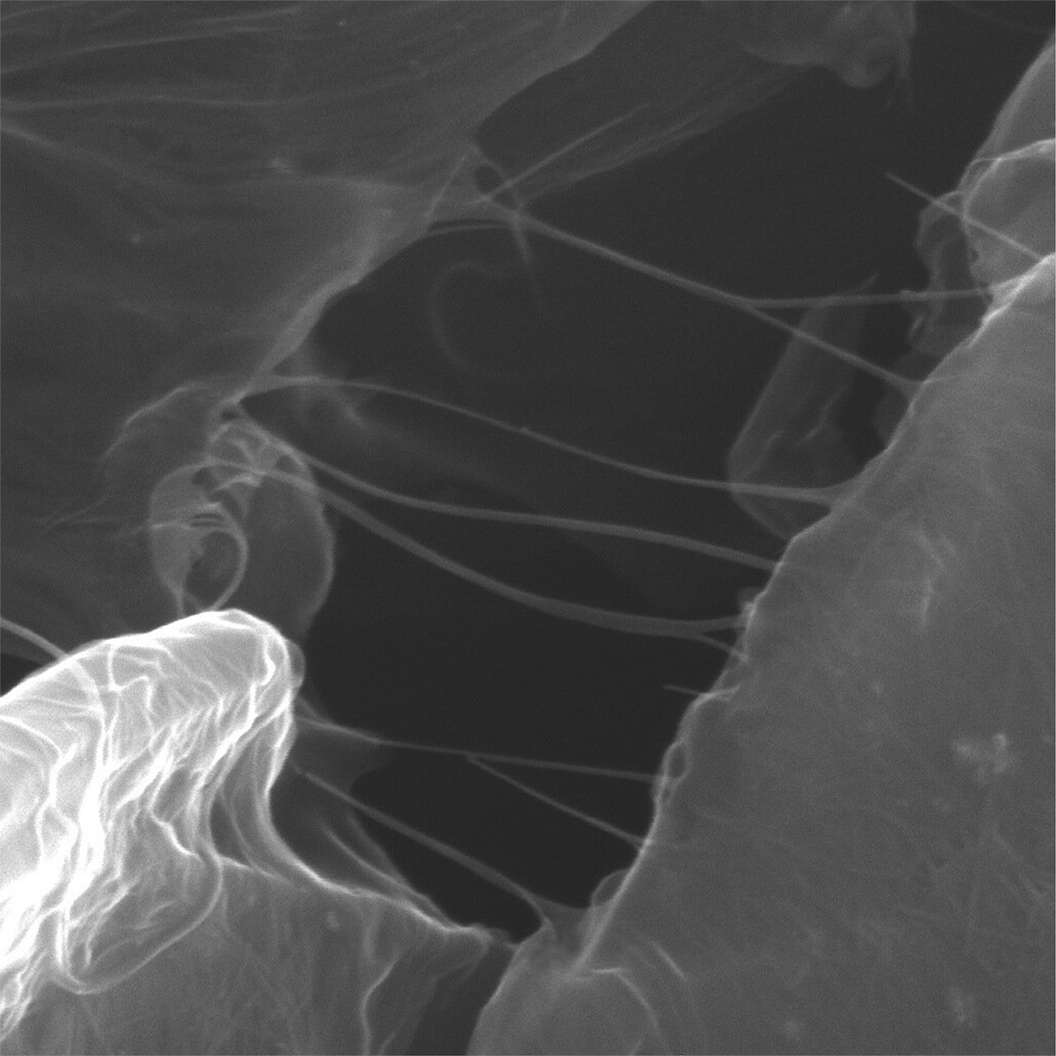

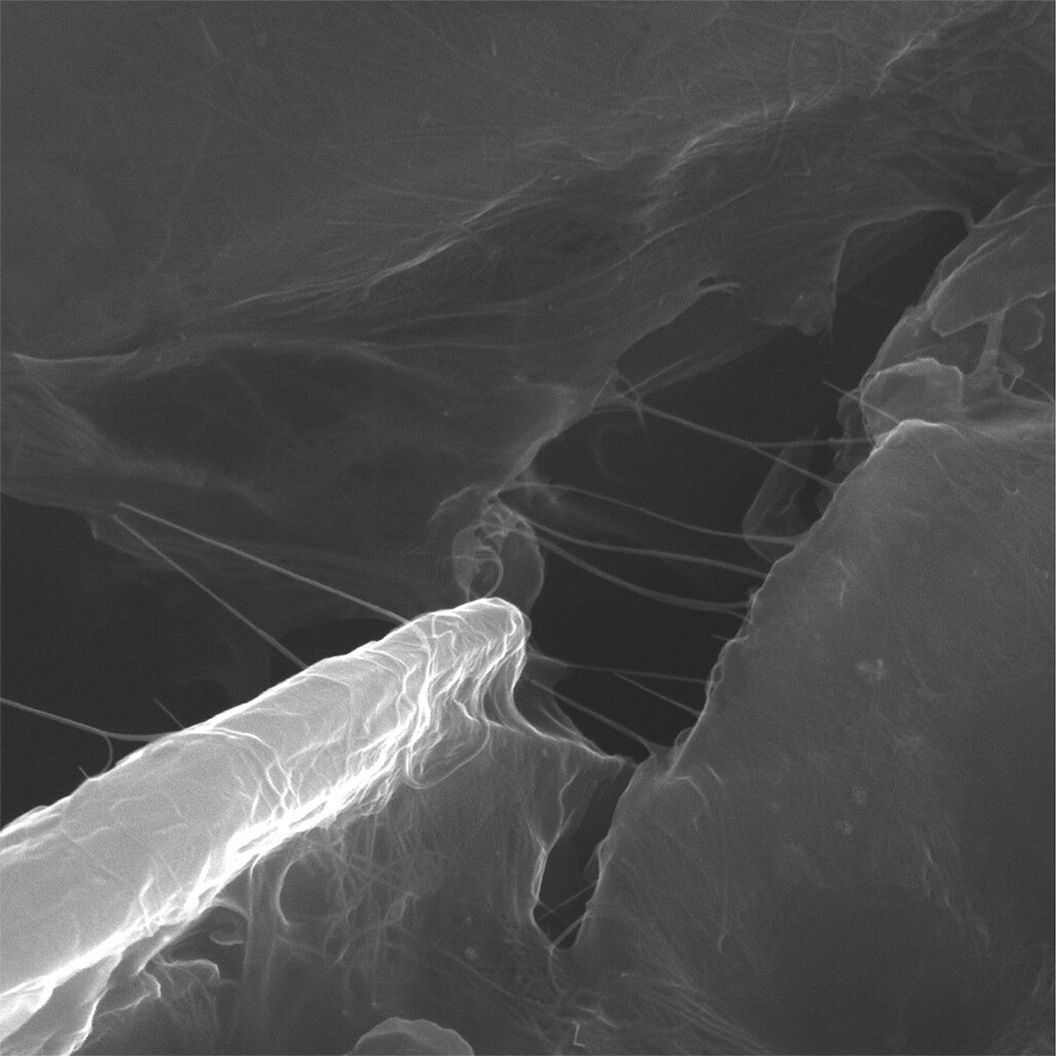

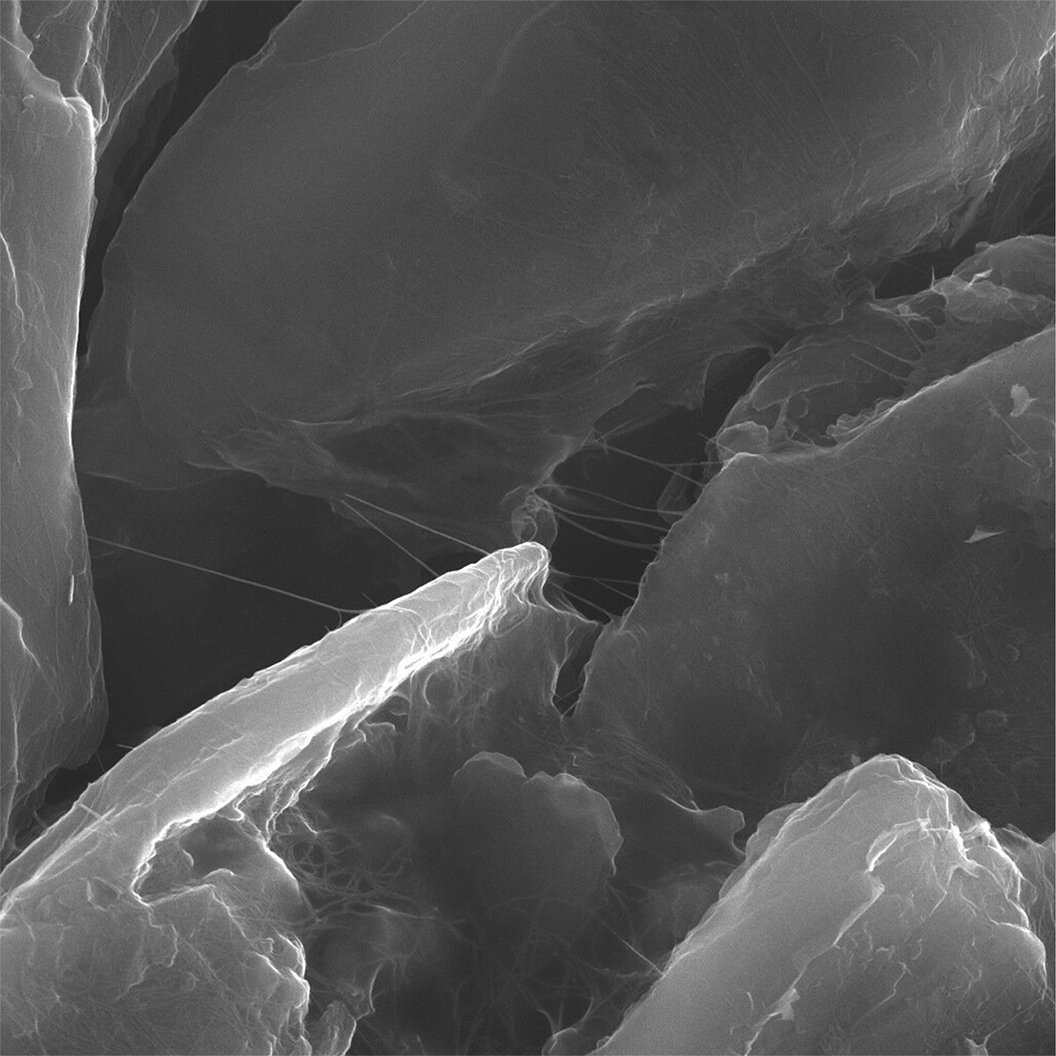

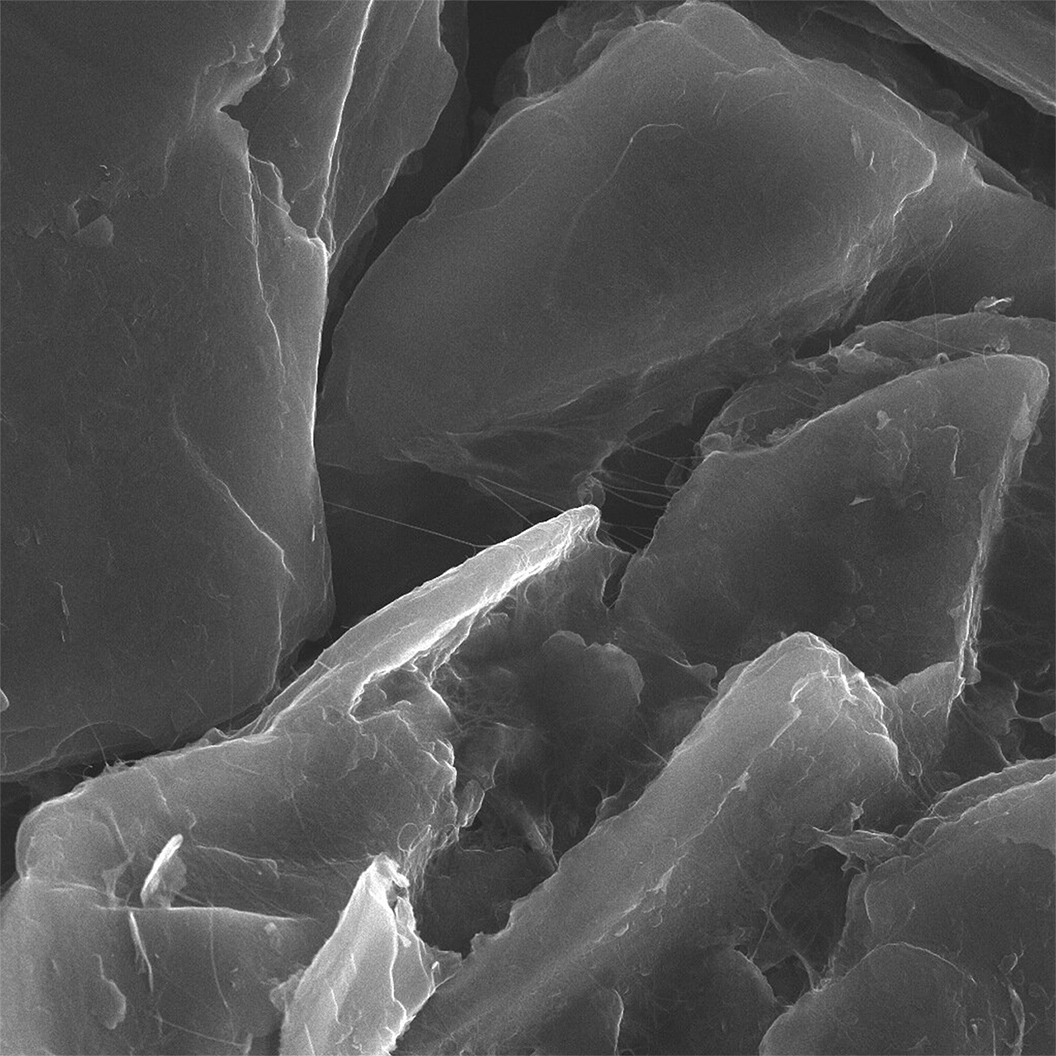

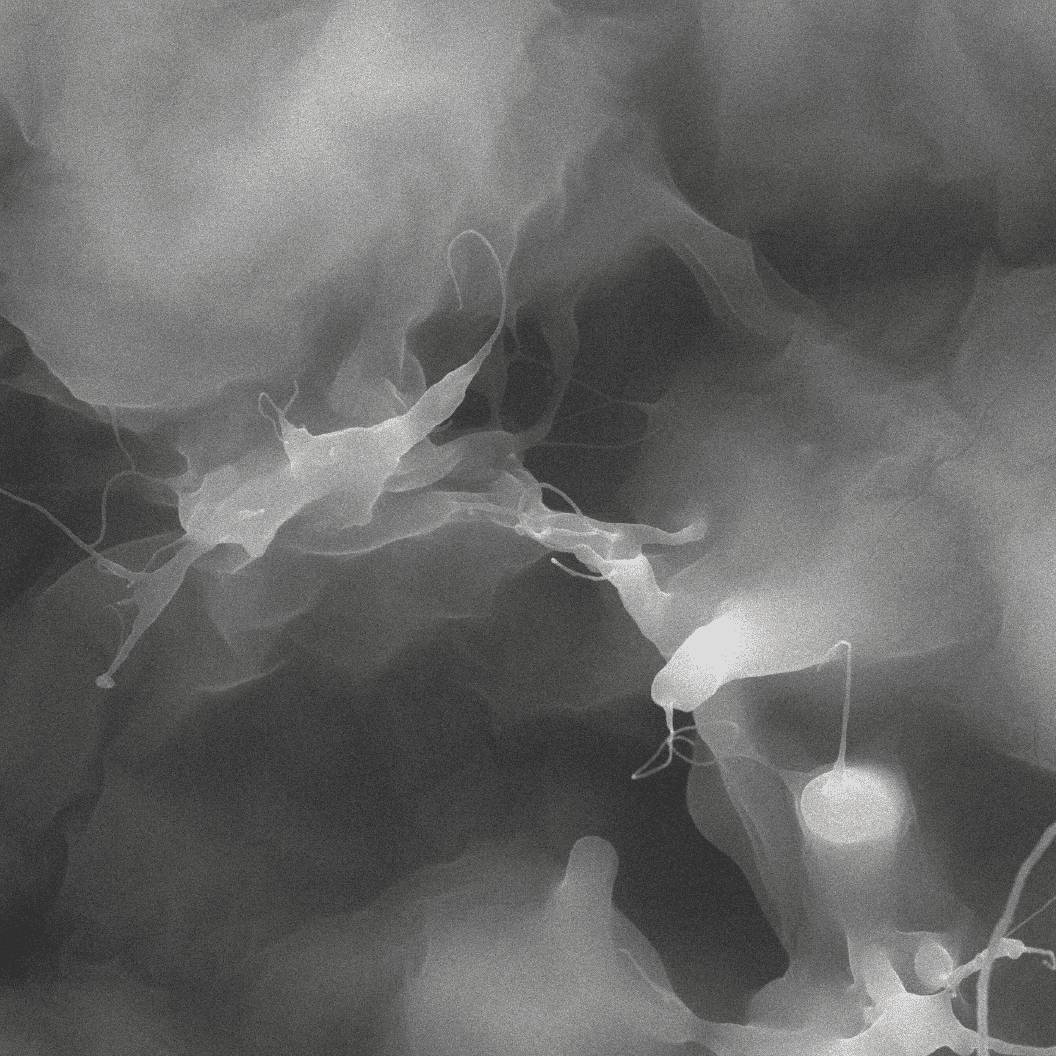

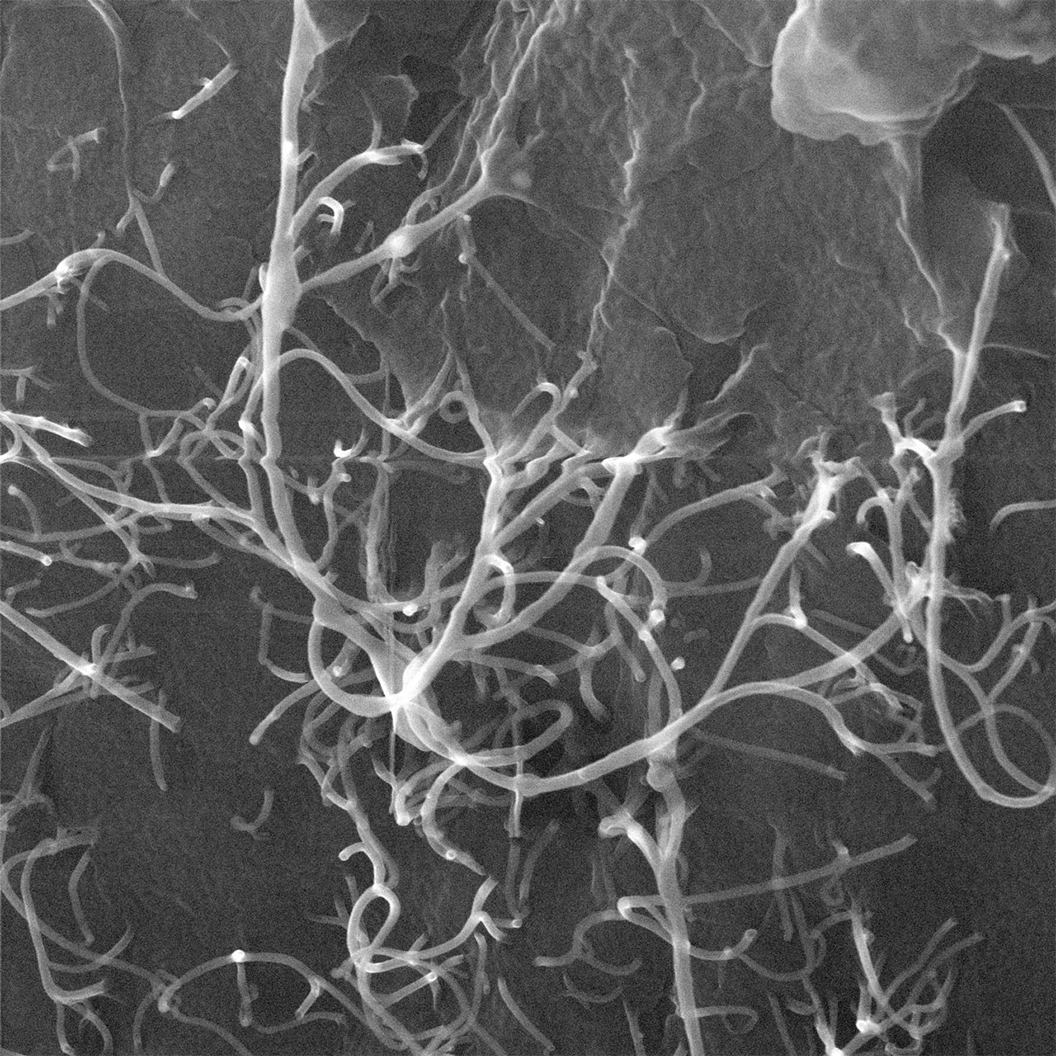

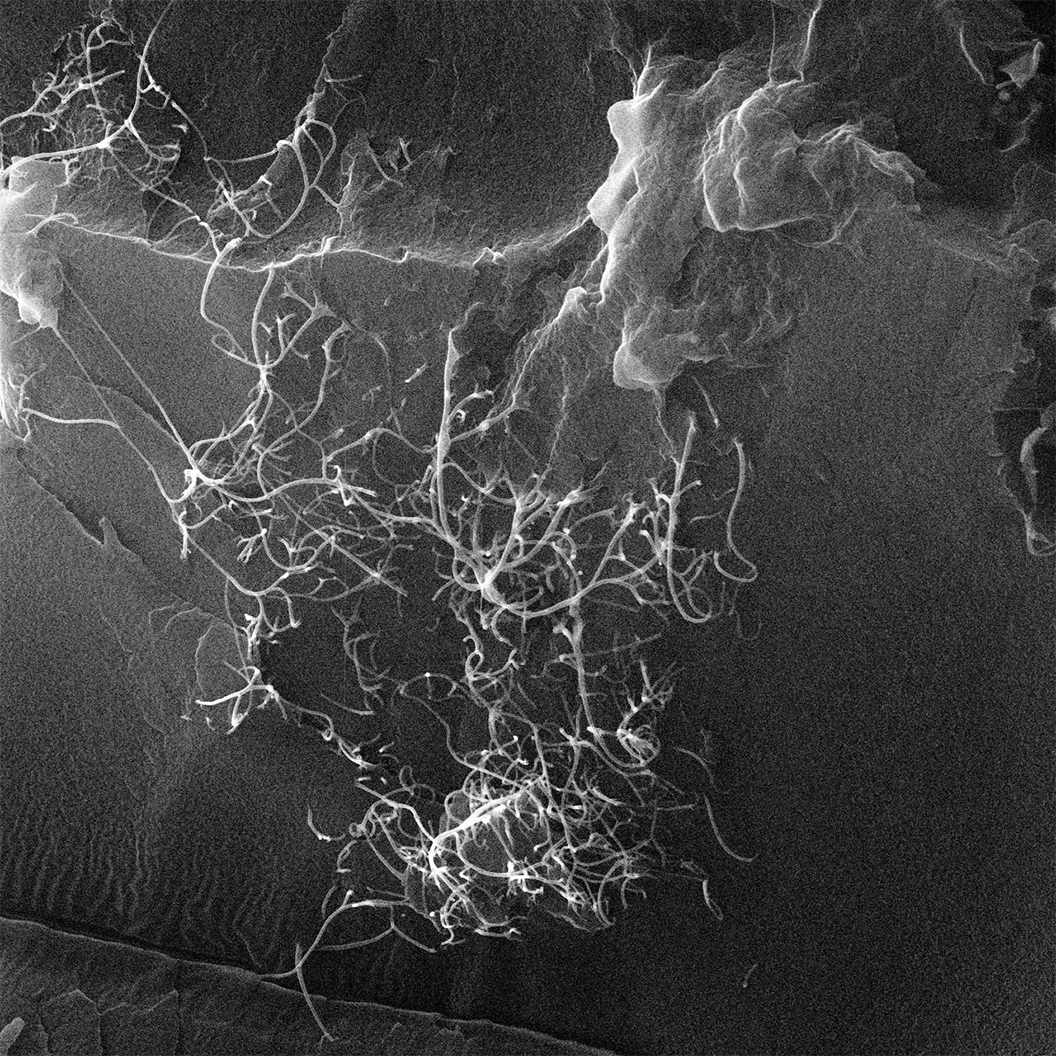

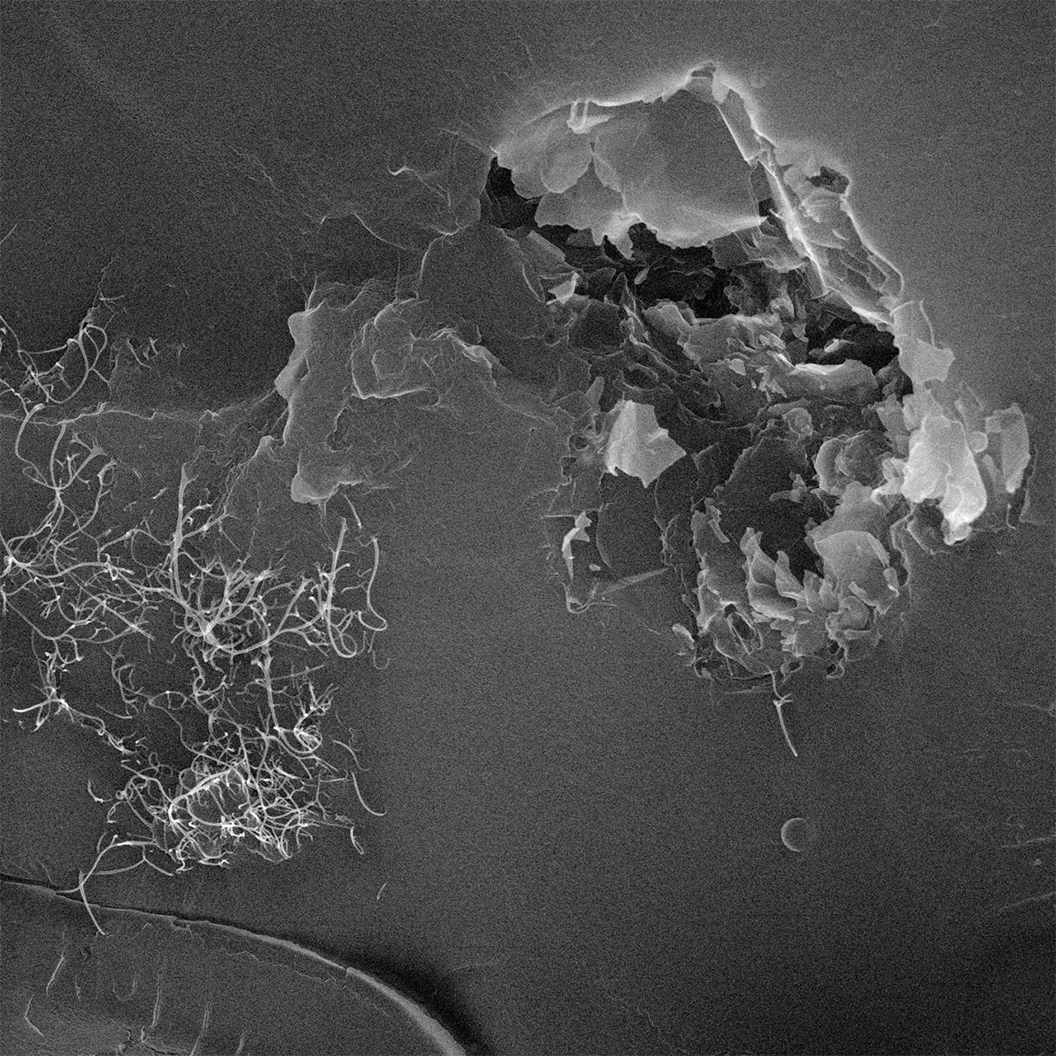

Graphene nanotubes, or single wall carbon nanotubes, are graphene sheets shaped as a tube. Their unique physical properties make them a universal additive that has potential applications across up to 50% of the global materials market.

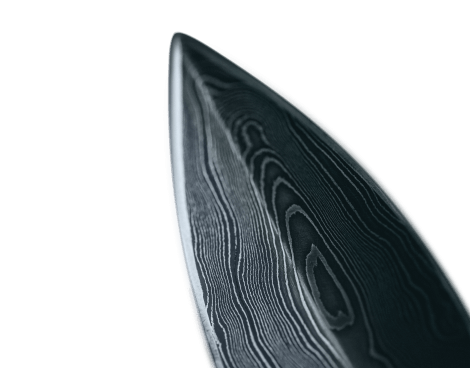

Despite the similarity in their names, single wall and multi wall carbon nanotubes differ in their properties and in the effects they have on materials, just like graphene (a single layer of carbon atoms) differs from graphite (multiple layers of carbon atoms).