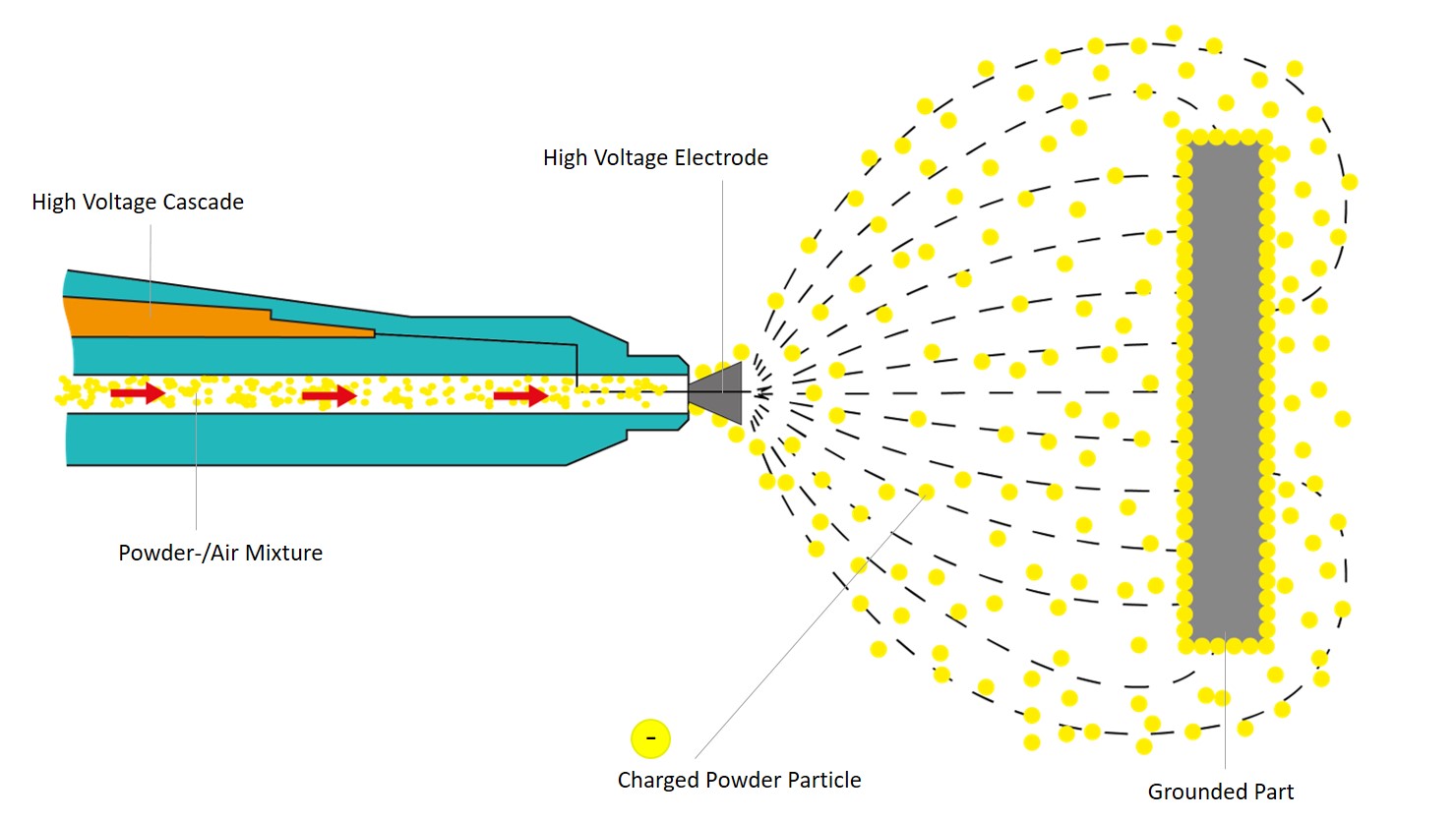

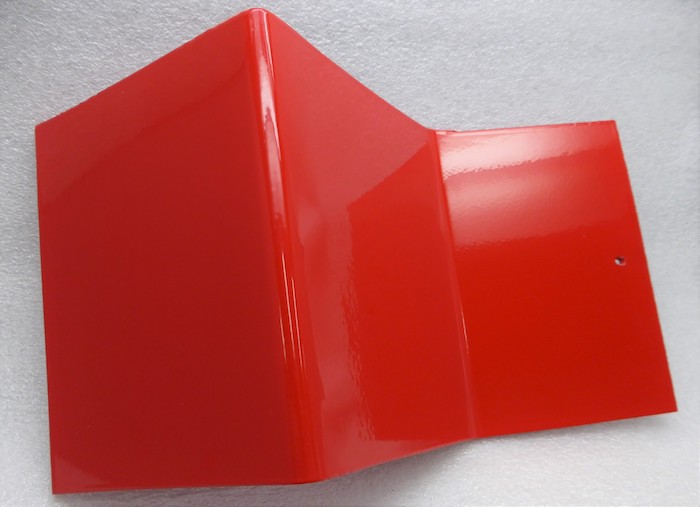

New conductive gelcoats with graphene nanotubes as a protecting layer on top of fiber-reinforced plastics (FRPs) grant engineers and designers the ability to produce special surfaces and uniformly coat all final parts regardless of their conductive and non-conductive nature. Ease of processing, flexibility in color effects, chemical resistance and zero emissions – powder coating on gelcoats offers a viable alternative to liquid painting of FRP parts in automotive, marine, aerospace, and even sanitary applications.

Fiber reinforced plastic (FRP) is valued for its strength and the freedom it offers designers but was always limited in the types of coatings that can be applied. Recent tests with the use of conductive gelcoats have demonstrated the possibility of using powder coating, which is a new step forward in coating technologies for thermoset composites.

“Demonstrating a number of obvious benefits, such as zero release of volatile organic compounds to the atmosphere, solvent-free formulations, good protection and decorative performance, powder coatings are mostly applied electrostatically and used to coat metallic parts. Being able to spray powder coatings on FRP, which is an insulator, is a significant benefit,” said Anna Meisczuk, Specialist for Powder on Plastic and PIMC Applications at TIGER Coatings. “What brings added value is that we were able to maintain simple processing, wide color possibilities, including the complete range of effects, excellent performance, and chemical resistance.”

The new conductive gelcoat range results from BÜFA Composite Systems knowledge and experience in developing solutions for polyester resins with graphene nanotubes. “TUBALL graphene nanotubes by OCSiAl are the key that makes it possible to combine permanent and stable resistivity of 10^6 Ω/sq. Such characteristics are already established in the BÜFA®-Conductive-Tooling Gelcoat series. The latest new gelcoat types are tailored for powder coating use. We believe it opens up new prospective application fields, where high-performance and tailor-made composites solutions are essential,” said Jens Wolters at BÜFA Composite Systems.

Conductive thermoset resins like polyester, epoxy, vinyl ester and others modified with graphene nanotubes have already found a wide range of applications in pipes and tanks, ventilation systems, print rollers, control boxes, floor coatings at industrial production plants, and molds. A high-gloss, homogenous surface, anti-dust effect, safer and easier demolding process, and shorter working cycles are the benefits of conductive tooling gelcoats frequently cited by mold producers.

About TIGER Coatings

TIGER Coatings was founded in 1930 from a paint shop and today is an internationally active family business with eight production sites worldwide, three research and development centers and a sales network in about 50 countries. The sixth largest powder coating manufacturer in the world, headquartered in Wels, Austria, generated sales of 300 million euros in 2019 with about 1,250 employees.

The high-quality coating solutions from TIGER – powder coating and digital inks for industrial printing systems – guarantee long-term value retention and are used, for example, on facades, car wheels, furniture, refrigerators or machines. With TIGITAL® 3D-Set, TIGER continues to drive innovation and offers completely new thermoset materials for SLS 3D printing.

About OCSiAl

OCSiAl is the world’s largest manufacturer of graphene nanotubes and owns the only scalable technology that can synthesize graphene nanotubes in industrial volumes. A graphene nanotube is a rolled-up sheet of graphene. The advantages of TUBALL nanotubes in comparison with standard additives are related to their unique combination of properties, including high electrical and thermal conductivity, strength and flexibility.

To simplify nanotube handling, OCSiAl has developed its TUBALL™ MATRIX nanotube concentrate product line that allows nanotubes to be used directly in standard manufacturing processes. As little as 0.1% of the concentrate is enough to improve a material’s properties significantly. So far, OCSiAl has developed TUBALL™-formulated technologies for electrochemical power sources, elastomers, composites, plastics, paints and coatings. The current production capacity is 80 tonnes per year. In 2023, the company will launch the first train of a new synthesis facility in Luxembourg with an annual capacity of up to 100 tonnes. Headquartered in Luxembourg, OCSiAl is represented in the USA, Russia, Korea, China, Hong Kong, Japan, Israel, India, Malaysia, Mexico, Australia, and Germany.

tuball.com/nanotubes-for/gelcoats-moldcoats

About BÜFA Composite Systems

The company BÜFA Composite Systems is part of the Oldenburg-based BÜFA Group, with headquarters in Rastede. The independent subsidiary was founded in 1964 as BÜFA Reaktionsharze.

We produce composite materials of the highest quality for renowned companies in the automotive, rail and commercial vehicle, wind power, construction, sanitation, tank and pipe industries as well as for boat building and swimming pools. Our customers receive tailored composite products and complete solutions. As a provider of systems, we also have outstanding expertise in service provision, as well as in engineering and applications. With the help of numerous European sales companies and distribution partners, we guarantee a reliable international service network.

Pictures: TIGER Coatings GmbH u Co KG