The high loading levels required by conventional conductive agents can negatively impact the colour and transparency, the surface finish and the mechanical properties of coatings, so manufacturers are always looking for new solutions to avoid this. It is now widely recognised that single wall carbon nanotubes are one of the most promising cutting-edge materials that can make conductive coatings more efficient, durable and affordable.

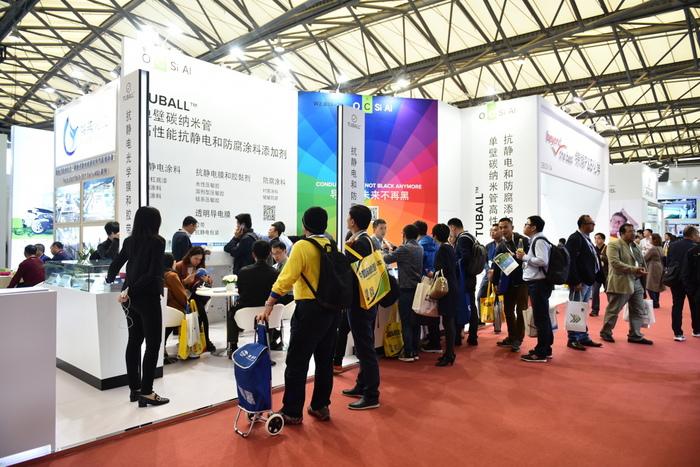

On 15–17 November at the ChinaCoat 2017 exhibition in Shanghai, OCSiAl, the world’s leading producer of single wall carbon nanotubes, presented its novel technologies based on TUBALL nanotubes, including concentrates for coatings applications.

There are two types of anti-static standards for coatings applications, namely conductive and anti-static. TUBALL-based products are specially designed to meet both standards. They can be used with the standard technology of paint production and provide permanent anti-static properties to water-based paints and coatings, while improving adhesion and abrasion resistance. A loading of just 0.03% of TUBALL nanotubes provides coatings with a surface resistivity of 10^6 Ω/sq, while reinforcing the structure and minimally impacting the material’s colour.

‘The many successful market-oriented applications of nanotubes from our partners all around the world have drawn the attention of ChinaCoat participants. The option of a multitude of bright colours in highly conductive coatings was previously impossible with any other carbon-based solution. TUBALL is providing manufacturers with access to a wider range of performance for both mechanical and conductive properties,’ commented Loyes Zhi, OCSiAl China Commercial Director.