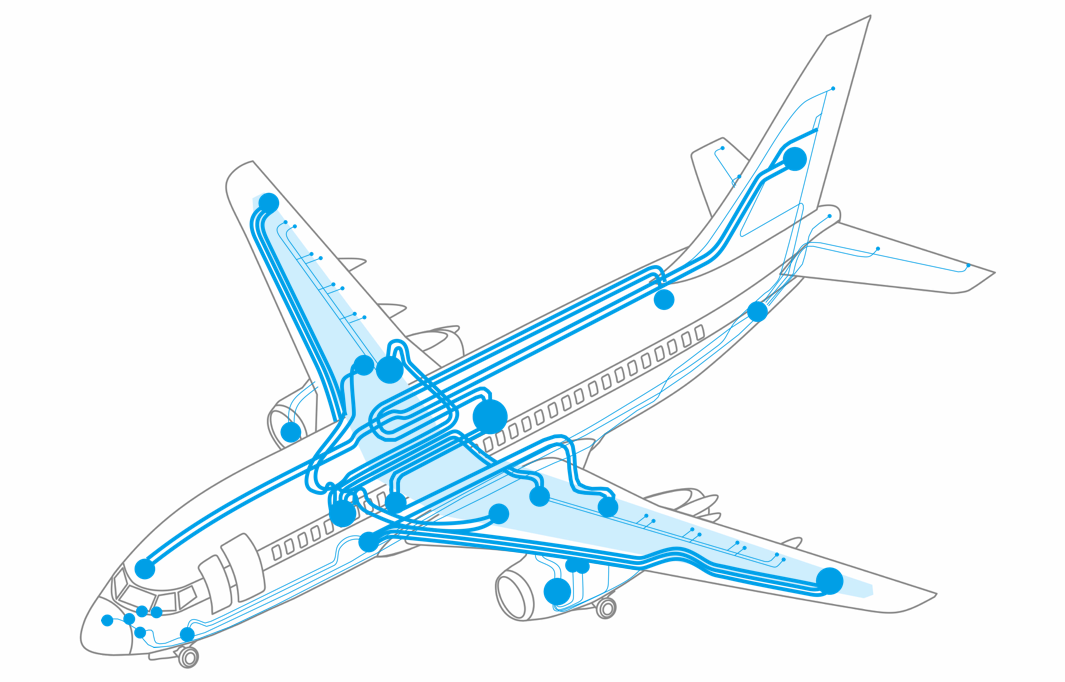

Butadiene-nitrile rubber (NBR) is widely used in a variety of industrial and vehicle applications. For example, aircraft fuel system hoses and soft fuel tanks all depend on the properties of NBR. The primary advantage of this type of rubber for such applications is its resistance to low temperatures and ability to withstand heavy dynamic loads. SWCNT increase strength of NBR compounds, which leads to longer service life and better safety of the end applications.

In a joint development project with one of OCSiAl’s customers, SWCNTs were introduced into the early stages of NBR production. As a result, residual deformation of the rubber decreased by half while strength and oil/gas resistance increased. SWCNTs slow the physical deterioration of the final compounds, which work under abrasive and dynamic loads in harsh environments, including oils and chemicals. This would significantly increase durability of products for the oil, aviation and automobile industry.

NBR enhanced with nanotubes is the material of tomorrow, providing customers with a simple way to create more durable products. Throughout the rest of the year, OCSiAl and partners are planning to expand this project to include gasket products that would be resistant to oil, gas, a wide range of temperatures and aggressive substances.