- Graphene nanotubes make it possible to preserve high thermal and chemical resistance together with stable electrical conductivity

- Nanotube-enhanced electrically conductive PPS for battery packs perfectly complies with Li-ion battery pack system standards.

- Manufacturers have a solution for optimizing performance, energy output, and cost structure of their battery packs to meet the trends of the booming EV market.

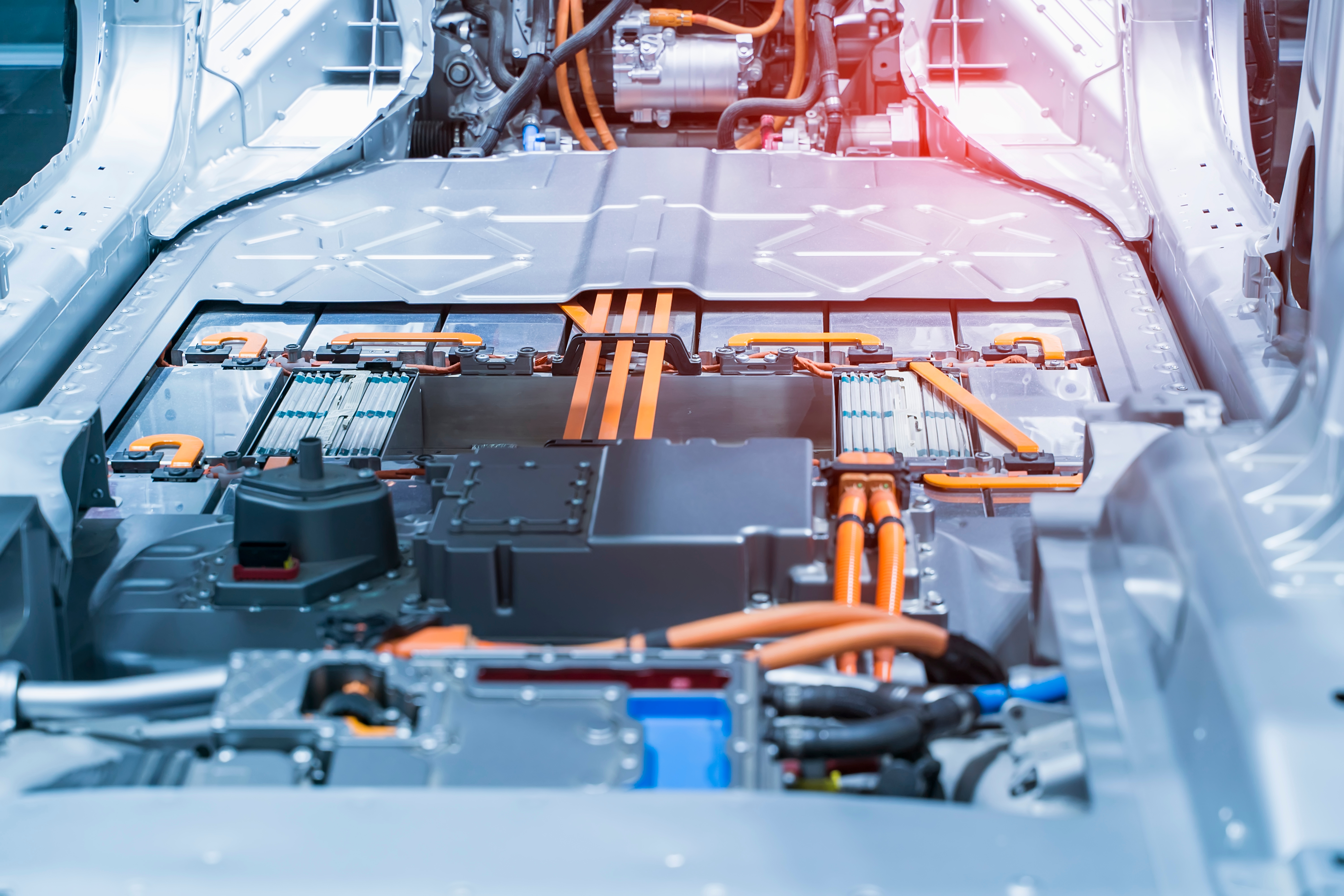

Some 6.6 million electric vehicles were sold around the world in 2021. Market trends are leading electric vehicle battery pack manufacturers to improve battery characteristics, design, and cost-efficiency, aiding their adoption by the mass market.

A leading Chinese company in engineering plastics and new composite materials, Genius, together with OCSiAl, the world leader in the production of graphene nanotubes, has developed an advanced engineering solution for battery packs. They utilize reinforced glass fiber filled polyphenylene sulfide (PPS), with 0.3 wt.% graphene nanotubes replacing 10 wt.% conductive carbon black. The final parts show surface resistivity of 103 Ohm/sq after injection molding and fully meet the high battery standard.

Traditional agents added into thermoplastics have numerous drawbacks, increasing the number of out-of-spec parts and forcing producers to make compromises in performance: carbon black can’t provide stable and homogenous electrical conductivity, while carbon fiber can’t provide targeted low resistivity.

“In contrast to conventional additives, graphene nanotubes used at an ultra-low effective concentration make it possible to preserve the outstanding chemical and thermal performance of high glass filled PPS, including its dimensional stability at ambient conditions. What’s more, they preserve the required MFI level and impact viscosity, thereby providing acceptable injectability, which is hard to achieve using multi-wall carbon nanotubes,”- said Loyes Zhi, Managing Director of Sales and Commercial for Greater China & SEA, OCSiAl Group.

An easy-to-handle pre-dispersed concentrate of nanotubes, TUBALLTM MATRIX, allows good processability and the freedom to incorporate other functional ingredients. Permanent homogenous resistivity without “hot spots,” retained color, good surface quality, and high performance of the battery pack reduce the assembly costs of battery enclosures, increasing their safety, durability, compliance, and affordability, which are the major drivers on the EV market.

---

Headquartered in Luxembourg, OCSiAl is the world’s largest manufacturer of graphene nanotubes, also known as single wall carbon nanotubes. It employs more than 450 people worldwide in locations including the United States, Europe, China, India, Japan, and South Korea. Current annual production capacity is 100 tons, which accounts for 97% of the world’s graphene nanotube production capacity. OCSiAl has developed more than 40 graphene nanotube products aimed at enhancing polymer materials, including thermosets, thermoplastics, elastomers, and electrochemical power sources.

Websites: ocsial.com, tuball.com

Genius, established in 1992, is a high-tech company dedicated to the research, development, and manufacture of polymer materials such as engineering plastics and new composites. Genius has a profound accumulation of patent resources, technologies, and solutions for the new material industry. The company’s business covers automobile, construction, electrical, IT, water conservancy, petrochemical, railway transportation, new energy, communications, and other fields. Among partners are many well-known domestic and foreign customers such as Volkswagen, GM, Bosch, TCL International Electric, Mitsubishi Electric, Hitachi, Electrolux, Panasonic, Sharp, Samsung, LG, Walmart, China CRRC, CIMC Group, Huawei, and BYD.

Website: geniuscn.com