- OCSiAl’s new silicone laboratory in Serbia brings a complete innovation chain from formulation to pilot production to accelerate nanotube-based silicone development.

- Graphene nanotubes enable a new class of conductive, durable, flexible silicones—from EV components to wearable sensors and antistatic robotic parts—delivering performance that traditional fillers can’t match.

The silicone industry is moving toward smarter, safer, and more energy-efficient materials. OCSiAl, the global leader in nanotechnology and the producer of TUBALL™ graphene nanotubes, has opened a new laboratory for liquid silicone rubber (LSR) and room-temperature-vulcanizing (RTV) systems and added a product line for silicones to its rapidly expanding production site in Serbia—built to keep pace with the fast-rising global demand for graphene nanotubes.

The silicone laboratory is fully equipped for formulation, curing, molding, and electrical testing. The lab focuses on developing graphene nanotube solutions for silicone systems across industries, leading the shift toward electrification and intelligence. The demand for graphene nanotubes continues to rise, and the company is steadily and responsibly expanding its capacities in every direction. This includes both production and R&D facilities, ensuring that everything delivered to the end customer meets the highest standards—standards set by the graphene nanotubes themselves.

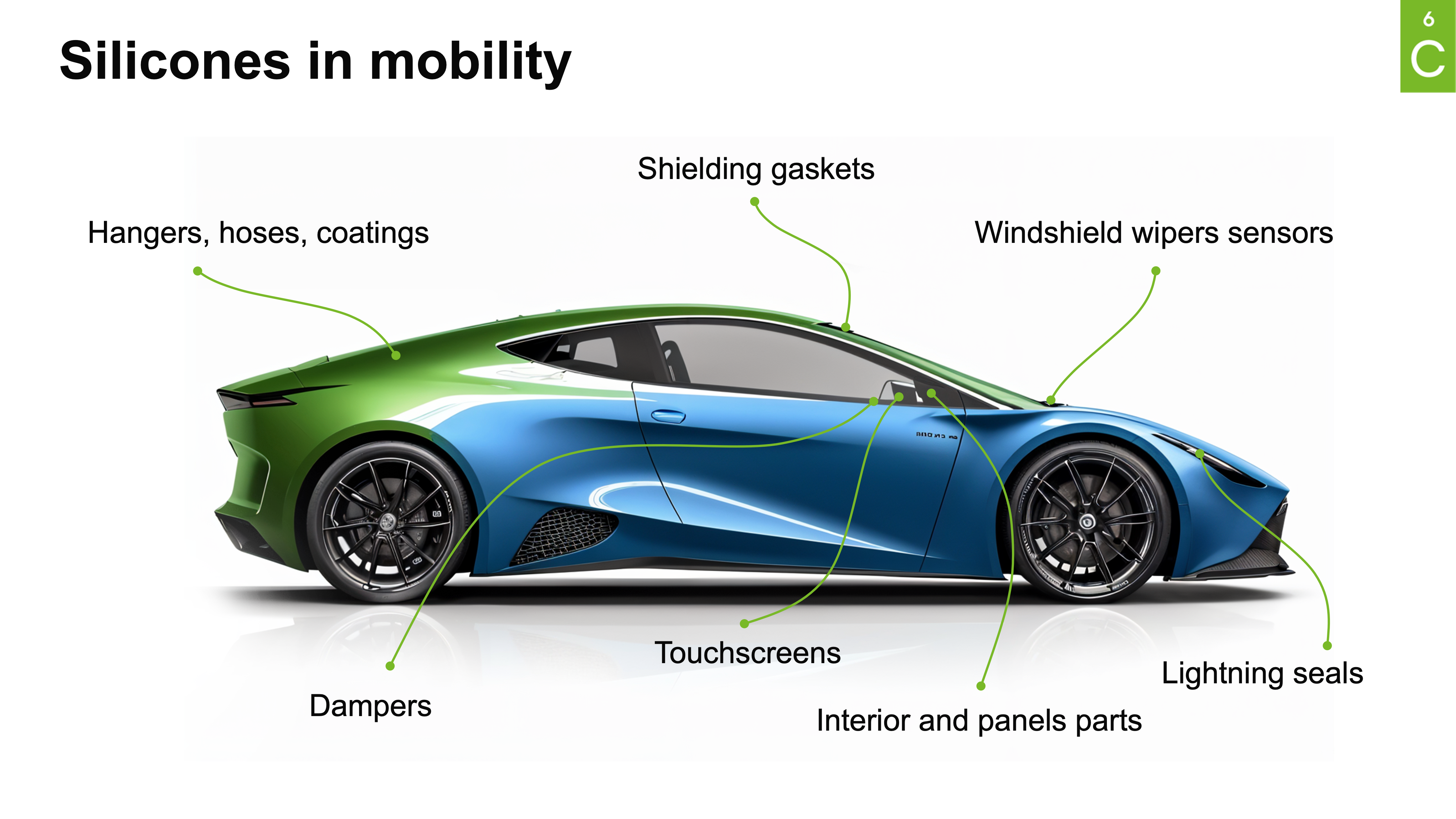

In the silicone industry, graphene nanotubes make it possible to create materials that are permanently conductive while still being flexible, soft, and colored as silicone should be—a combination long considered incompatible. In automotive applications, this means unlocking the whole conductive spectrum, from antistatic to EMI-shielding silicones that maintain elasticity and durability even under extreme mechanical and thermal stress. Beyond mobility, robotics benefit from antistatic protection granted by graphene nanotubes, ensuring consistent precision in sensitive components, such as silicone finger prostheses compatible with touchscreens, featuring electrical resistance between 5 and 200 Ω—without skin contamination and without releasing carbon onto the surface. Wearable and wellness devices gain reliable conductivity and comfort, enabling accurate, real-time body data monitoring.

With accelerated research, stronger partnerships, and a fourfold increase in graphene nanotube production capacity next year, OCSiAl aims to make graphene nanotubes an accessible standard for advanced materials worldwide, helping European and USA manufacturers design lighter, smarter, longer-lasting products that will shape future technologies.