- Graphene nanotubes give PET fibers stable, permanent electrical conductivity meeting safety standards for electronics, clean rooms, and workwear.

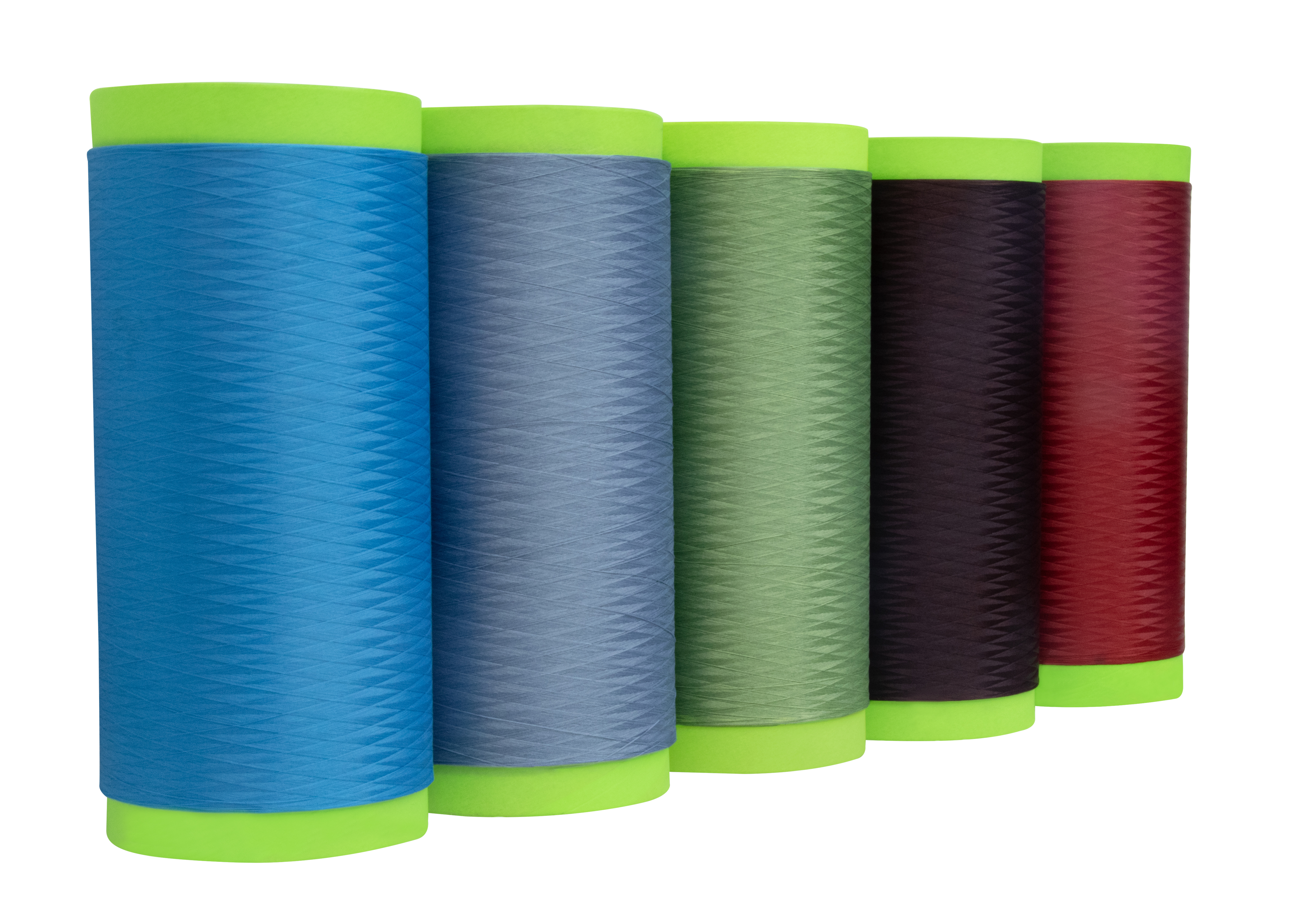

- Compared to previous-generation additives, nanotubes offer superior functionality and maintain flexibility, durability, hypoallergenic properties, and customizable color options.

- Expected further applications for innovative PET fibers include foldable electronic components, wearable tech, and protective clothing.

Polyethylene terephthalate (PET) fibers, valued for their high strength, low weight, and resistance to moisture, UV radiation, and chemicals, are essential in various high-performance applications. But electronics, clean room environments, and industrial workwear demand an additional functionality for insulative fibers: electrostatic discharge protection. Traditionally, metal wires or carbon black were used to achieve conductivity in thermoplastic polymer fibers, which often limited design options, could cause allergic reactions, and could result in difficulties with color fastness, especially under rigorous testing standards such as AATCC TM61. More importantly, the physical properties of carbon black-based conductive fiber are insufficient for this purpose; the fiber must be processed into a composite yarn before weaving.

Taiwan-based YAO I Fabric Co., Ltd., a prominent manufacturer of specialty fibers, has unveiled innovative conductive PET fibers with the brand name FLEX™ Yarn that are enhanced with TUBALL™ graphene nanotubes from OCSiAl. With a nanotube dosage of just 0.001 to 0.05 wt.%, FLEX™ Yarn exhibits stable electrical resistances of 105~106Ω/cm and 102~103Ω/cm, while retaining its flexibility, color vibrancy, and hypoallergenic properties. Ready-to-use nanotube-based solutions drive streamlined production by allowing nanotube integration in unique carbonization fusion technology (CFT) spinning processes, saving both time and cost for customers.

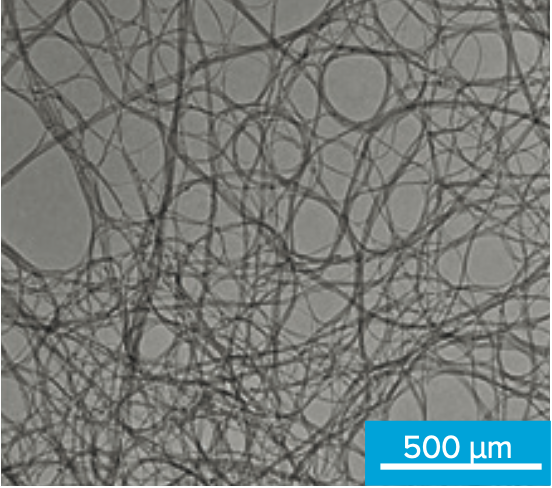

“The ultralong structure of graphene nanotubes allows them to form a 3D network inside the material throughout its entire volume, ensuring uniform conductivity across the fiber without carbon release. This enhances anti-static and electromagnetic interference (EMI) protection without compromising color or comfort,” said Ray Lu, Senior Manager, YAO I Fabric Co., Ltd.

“The series of FLEX™ Yarns with graphene nanotubes offers a sustainable solution, combining the durability and recyclability of PET with the high efficiency of TUBALL™ at an ultralow dosage. The enhanced functionality of this fiber makes it a multipurpose material for high-tech applications,” added Otis Wang, General Manager, YAO I Fabric Co., Ltd.

“Graphene nanotube-enabled PET fibers are an ideal material for use in foldable electronic components, wearable tech, and protective clothing,” commented Albert Lin, Sales Director Taiwan, OCSiAl Group. “These fibers deliver a unique combination of aesthetic appeal, comfort, and functional performance for modern industrial needs.”

---

About OCSiAl

Headquartered in Luxembourg, OCSiAl is the world’s leading manufacturer of graphene nanotubes, also known as single wall carbon nanotubes. OCSiAl produces high-purity graphene nanotubes on an industrial scale under the TUBALL™ brand name. OCSiAl has developed and is marketing globally a wide range of nanotube products for electrochemical power sources and various polymers and creates fundamentally new products based on them.

Website: tuball.com

About YAO I

Founded in 1973 in Taiwan, YAO I Fabric Co., Ltd. is a leading manufacturer of high-performance monofilaments and technical textiles. Its diverse product range includes fishing lines and sports string, industrial yarn, pet mats, automotive seat covers, sound-absorbing and stretch materials, and textiles for electronics and footwear. With factories in Taiwan, China, and Vietnam, YAO I serves industries from automotive to electronics, delivering durable, eco-friendly textile solutions.

Websites: YAO I Fabric Co., Ltd., FLEX