- Shanghai Haiyi Scientific & Trading Co., Ltd (“Shanghai Haiyi”) and Shenyang Huijing Nano Technology Co., Ltd (“Shenyang Huijing”), licensed producers of TUBALL BATT nanotube dispersions for anodes and cathodes, have announced plans for a several-fold capacity increase by the end of 2025 to meet customer demand.

- The companies supply all leading battery cell manufacturers in China with their high-quality dispersions produced in accordance with the strictest OCSiAl quality standards and confirmed by audits from battery cell producers.

- OCSiAl is supporting these expansion plans by launching a new nanotube synthesis plant in Serbia in October 2024.

Due to the exponential growth in demand for OCSiAl’s single wall carbon nanotube dispersions in the battery market, Shanghai Haiyi and Shenyang Huijing are accelerating their plans to expand their production capacity of TUBALL BATT H2O dispersions for anodes and TUBALL BATT NMP dispersions for cathodes by the end of 2025. Shanghai Haiyi plans to increase the overall capacity of TUBALL BATT to 27,000 tonnes of dispersion per year. Shenyang Huijing is scheduled to reach 25,000 tonnes of TUBALL BATT per year. These volumes correspond to the current needs of the Asian battery market.

“Single wall carbon nanotube dispersions are now widely used in most lithium-ion battery systems, and China’s energy market offers significant potential for new developments. Shanghai Haiyi will cooperate with each new battery cell producer to explore more new application scenarios of single wall carbon nanotubes, leveraging their technical characteristics and supporting sustainable and healthy development of China’s new energy sector,” said Mr. Zhu Yajun, Marketing Director of Shanghai Haiyi Scientific & Trading Co., Ltd and General Manager of Haiyi Hitech Material (Jiangsu) Co., Ltd.

“The expansion by Shenyang Huijing is a decision made after thorough market research and based on the growing number of high energy density and fast charging projects, as well as firm confidence in OCSiAl’s leading single wall carbon nanotube technology,” stated Mr. Xu Yongcheng, General Manager of Shenyang Huijing.

OCSiAl confirms its full support for both partners’ plans. “We are committed to supporting Shanghai Haiyi and Shenyang Huijing in meeting rapidly growing market demand by investing in new OCSiAl nanotube synthesis plants. In a few months—on October 29, 2024—we will launch a synthesis facility in Serbia. This is an industrially scalable nanotube synthesis unit that will be replicated in our further production expansions. The synthesis expertise stems from OCSiAl’s unique production knowledge of single wall carbon nanotubes, accumulated over nearly 15 years of continuous research and development. No other company has such deep technical expertise in single wall carbon nanotubes and experience of introducing them into all battery formulations throughout the global market,” said Loyes Zhi, OCSiAl General Manager for Great China and SEA.

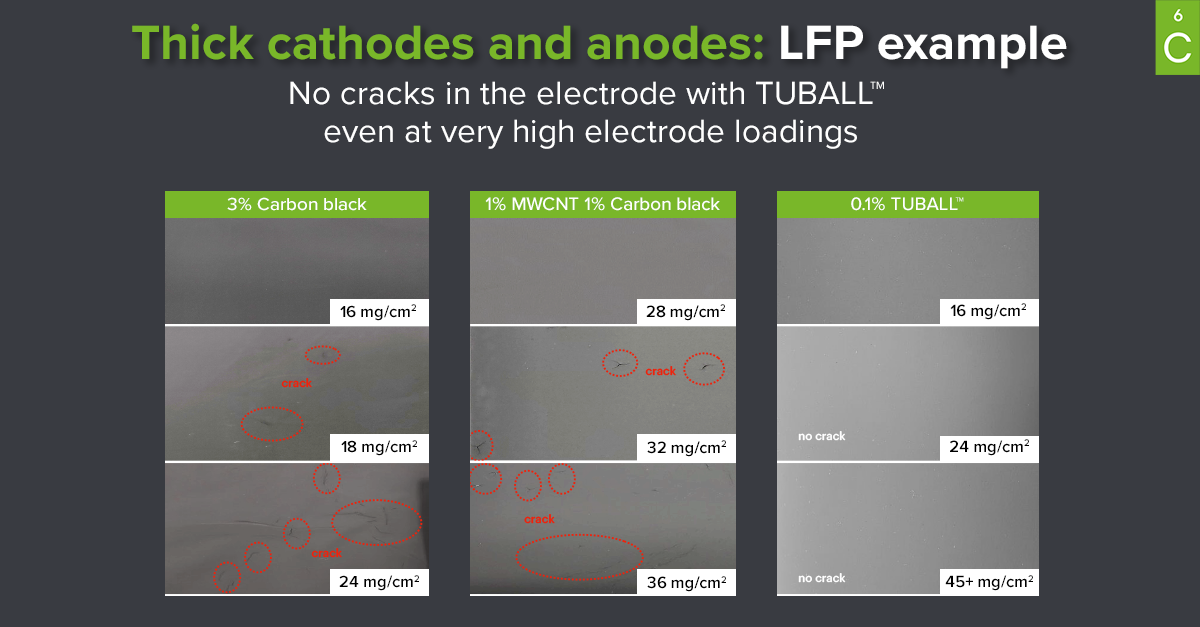

Licensed partners follow OCSiAl’s high quality management standards, which have been confirmed by Chinese and global cell manufacturers in their audits of dispersion facilities in China. OCSiAl partners have been delivering single wall carbon nanotube solutions to the Chinese market for more than eight years. Being nature’s longest and most flexible material for conductivity and reinforcement of electrodes, single wall carbon nanotubes can connect electrode particles at long distances in a highly reliable manner, surpassing the performance of other carbon-based materials for batteries. OCSiAl nanotubes in batteries make it possible to prolong cycle life, increase charge/discharge speed, and reduce the internal battery resistance of both anodes and cathodes. For many applications, they are proven to show exceptional results. For instance, OCSiAl nanotubes make it possible to produce record-thick electrodes and ultrahigh silicon content anodes.