- A facility to produce 3,000 MT of single wall carbon nanotube water-based dispersion annually has been completed in Serbia.

- An optimized and upgraded production unit has a 15-times higher than previous generation output per line and will serve as an industrially scalable unit for OCSiAl's further global expansion of production.

- Single wall carbon nanotubes have proven to be an irreplicable ingredient for silicon-rich anodes and single-crystal NCM (Nickel-Cobalt-Magnese) cathodes, and are being introduced as a performance enabler for emerging battery technologies such as dry battery electrodes (DBE) and solid-state batteries (SSB).

OCSiAl has completed the construction of a facility for the production of single wall carbon nanotube (SWCNT) dispersions in Serbia to support the manufacturing of high-performance batteries. Output has been contracted by leading global EV producers and collaborations with the world’s largest Li-ion battery cell manufacturers.

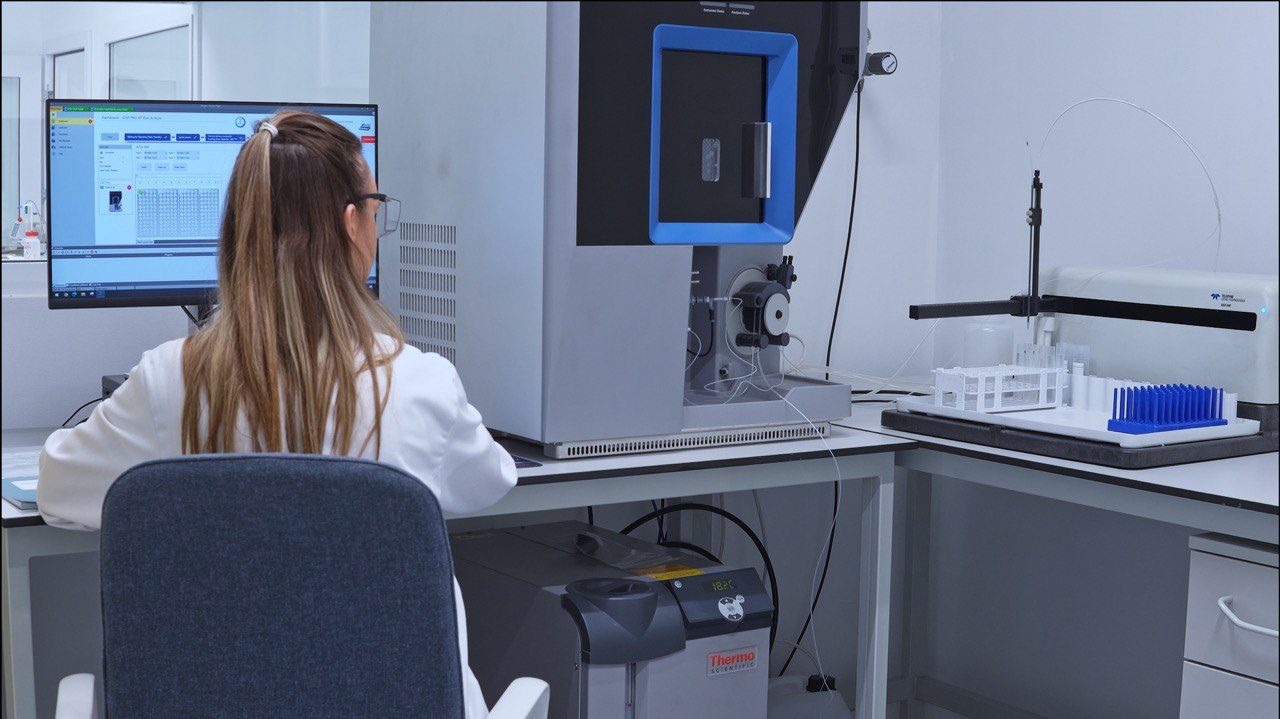

The facility features state-of-the-art equipment and clean room operated production lines, adhering to the highest quality standards. The current dispersion production unit is an optimized and upgraded version of the previous generation, offering 15-times higher output per unit and the capability to produce up to 10 MT of dispersion per day. Scheduled to commence commercial production in the third quarter of 2024, this facility employs an industrially scalable unit for SWCNT dispersion production, which will be blueprint for OCSiAl’s future expansions, elsewhere in Europe, Asia, and the US.

SWCNTs, known for their unique intrinsic properties, are nature’s longest and most flexible material for conductivity and reinforcement of battery electrodes, outperforming other carbon-based additives used in batteries such as multiwall carbon nanotubes or carbon black.

The new facility will produce water-based SWCNT dispersions for multiple EV and consumer electronics projects to enhance the performance of Li-ion battery cells with energy-dense, silicon-rich, or fast-charging graphite anodes. The usage of SWCNTs in these trending battery technologies makes it possible to forestall dramatically the degradation of the anode by creating a robust electrical network inside the electrode, which ensures that electrode particles stay electrically connected to each other under the harsh conditions that occur in the electrode during battery charging and discharging.

Together with these already widely popular applications of SWCNTs in batteries, nanotubes are starting to gain popularity in emerging next-gen battery cell technologies, such as dry battery electrodes (DBE), semi-solid batteries, and single-crystal NCM materials, as well as in energy storage systems (ESS) with record-thick LFP (Lithium-Iron-Phosphate) cathodes.

In 2023, OCSiAl expanded its battery product portfolio by introducing high-content SWCNT dispersions, providing cost-saving benefits to customers. The next step in its expansion of the global production and supply chains is the launch of an SWCNT synthesis facility and research hub in Serbia, scheduled for October 2024. By 2027, the company plans to launch its biggest production site in Luxembourg to further enhance the resilience and sustainability of OCSiAl’s European supply chain.