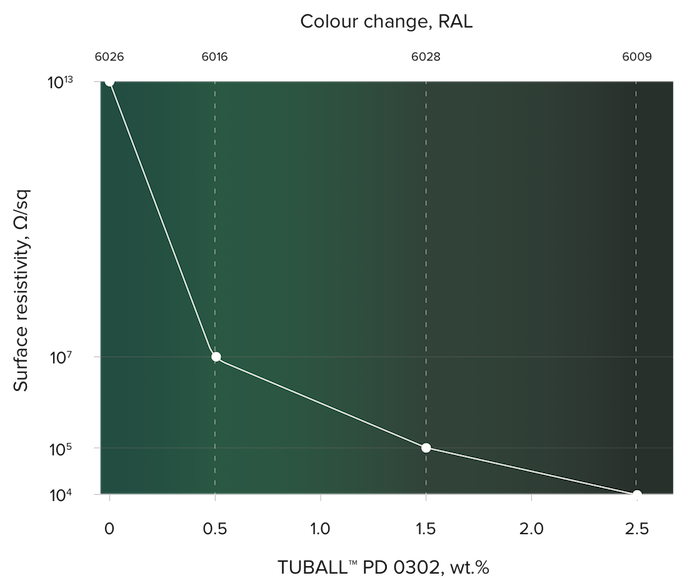

With their unique properties, graphene nanotubes push PVC plastisol performance higher, to fully satisfy market demand for 10 5 – 10 9 Ω/sq resistivity, to preserve a permanent and stable form even after harsh working conditions, to maintain abrasion resistance, and to demonstrate flexibility in the colouring of final products. This all is possible with just 0.25–2 wt.% of graphene nanotube concentrate, recently developed by OCSiAl.

New technology is able to eliminate the common friction points in the usage of conventional anti-static additives, such as carbon black or ammonium compounds. Application of carbon black usually affects PVC plastisol’s mechanical performance very negatively, and turns final products black, whereas ammonium compounds can become unstable over time and provide only humidity-dependent resistivity. On the top of that, processing itself is complex – carbon black influences the rheology of material and facilitates dust formation on the surface. Graphene nanotubes, which can solve all these challenges, bring vast improvements to the PVC plastisol industry.

Nanotubes create new business opportunities for conductive PVC plastisol manufacturers. They enjoy an overwhelming welcome in the mining industry, where assurance of safety is vital. Here are a few examples of graphene nanotubes blazing their own trail in this market. 0.4–0.5 wt.% graphene nanotube concentrate in PVC plastisol-based flexible ventilation ducting and fiberglass mesh for mining applications enable manufacturers to obtain a resistivity of 10 7 Ω/sq with maintained mechanical performance. PVC plastisol-based anti-static textiles and treadmill belts mapping out graphene nanotubes extensive application in industry. Uniform, permanent, stable and humidity-independent electrical conductivity – all guaranteed by graphene nanotubes.

%20%E2%80%94%20%D0%BA%D0%BE%D0%BF%D0%B8%D1%8F.jpg)

%20%E2%80%94%20%D0%BA%D0%BE%D0%BF%D0%B8%D1%8F.jpg)

Graphene nanotubes may have started as a “wonder-material,” but they are quickly becoming a conventional, economically viable technology for many industries. These tiny tubes are being used in a multitude of materials with increasing frequency, including PVC plastisol, polyurethane, epoxy, polyester, and acrylic polymers.